Blockchain & Supplier Trust – When and How to Use It

- gsriram87

- Sep 24, 2025

- 4 min read

Updated: Sep 25, 2025

Trust has always been the backbone of supply chains. For decades, companies relied on paper trails, audits, and bilateral contracts to build confidence in supplier relationships. While these tools worked in smaller, localized supply chains, they began to fall short as global supply networks expanded. Multiple tiers of suppliers, spread across different countries and regulatory systems, made it increasingly difficult to ensure compliance, traceability, and authenticity of data.

Digital solutions like Electronic Data Interchange (EDI) and siloed databases emerged to modernize trust management. They streamlined transactions but retained a critical flaw: they required one party to be the ultimate ‘owner of truth.’ This centralization left room for disputes and eroded confidence among smaller suppliers who feared being penalized.

Blockchain entered the conversation as a different kind of solution. By creating a decentralized, immutable ledger, it eliminated the need for a single source of authority. Everyone involved could validate information independently, making disputes less likely and data more reliable. While many early pilots faded, blockchain stayed because it solved a problem that other technologies couldn’t: verifiable trust across complex, multi-tier ecosystems.

Learning from Nissan’s Experience

A compelling example of blockchain in action comes from Nissan. In 2020, Nissan launched a blockchain-based platform to track certified parts across its supplier network. The initiative required key suppliers to participate, ensuring that every critical part could be validated against an immutable record. The goal was simple yet powerful: reduce counterfeiting, guarantee compliance, and provide peace of mind to both regulators and customers.

The program worked because it addressed a high-stakes problem. Safety-critical parts cannot afford ambiguity. With blockchain, Nissan created a transparent framework where suppliers could demonstrate part authenticity without additional overhead. Suppliers didn’t need to ‘learn blockchain’—they simply uploaded data into their existing workflows, while the technology quietly managed the trust mechanism in the background.

The lesson from Nissan is clear: blockchain works when the stakes are high and the value of trust outweighs the friction of adoption. By positioning blockchain as an invisible enabler rather than a new system to master, Nissan made it easier for suppliers to participate, ultimately strengthening the entire ecosystem.

Why Blockchain Stayed While Others Faded

Many digital solutions tried to address supplier trust. Central databases offered speed but left disputes unresolved because ownership of data remained centralized. Certification schemes and regular audits improved oversight but were costly and often reactive. What set blockchain apart was its ability to serve as a neutral, tamper-proof source of truth. It enabled multiple parties—often with competing interests—to validate data without relying on a single controlling authority.

This neutrality is why blockchain stayed while others faded. It addressed the trust gap that global supply chains had struggled with for decades. But blockchain’s staying power doesn’t mean it should be applied everywhere. Its complexities, costs, and onboarding challenges mean that selective use is the smarter path forward.

The Complexity Barrier

It’s important to clarify a common misconception: sub-tier suppliers don’t need to master blockchain technology to participate. They aren’t expected to write smart contracts or configure nodes. The technology is designed to work in the background. The real barrier is the additional complexity it introduces to already stretched suppliers. Participation often requires extra certifications, standardized data formats, and compliance checks. For small suppliers, these steps can feel burdensome and slow.

In practice, this complexity can discourage participation. Tier-3 and below suppliers may delay onboarding or resist sharing data altogether, ironically undermining the trust that blockchain was meant to build. The challenge isn’t about education—it’s about minimizing the hidden friction that comes with adopting blockchain programs.

When Blockchain Makes Sense

The key to unlocking blockchain’s value lies in applying it selectively. It is most effective in high-stakes scenarios where verifiable, tamper-proof data is essential for compliance, safety, and sustainability. Examples include:

- Carbon emissions reporting and Scope-3 sustainability metrics.- Conflict minerals tracking and ethical sourcing.- Fraud prevention in supplier certifications and audits.- Material composition details, critical for regulations and customer assurance.- Certified part verification, as demonstrated by Nissan’s program.

In these areas, the rigor of blockchain is justified. The ability to create immutable records protects OEMs from regulatory penalties, strengthens sustainability claims, and prevents reputational damage. These are not optional benefits—they directly impact financial performance and brand equity.

When Blockchain Doesn’t Add Value

Not all supplier interactions need the weight of blockchain. Routine communications such as notifying an OEM about a delayed shipment, sharing a small production update, or flagging a minor disruption can be handled more effectively through lightweight collaboration tools. In these cases, the additional friction of blockchain adds no real value and can slow responsiveness.

For these interactions, simplicity is key. Trust is not at stake in the same way it is for certified parts or compliance metrics. OEMs and suppliers benefit more from speed and ease of use than from tamper-proof audit trails.

A Balanced Approach to Trust

The future of supplier collaboration will not be built on blockchain alone. Instead, it requires a pragmatic balance: leveraging blockchain where the stakes demand it and complementing it with user-friendly tools for everything else. Suppliers should not feel like blockchain is being forced upon them. They should see it as an invisible enabler that solves specific problems while leaving room for agile, everyday collaboration.

OEMs can achieve this by educating suppliers about where blockchain adds value, while ensuring that participation remains simple. This builds trust not through over-engineering, but through thoughtful application of the right tools in the right context.

Closing Thoughts

Blockchain has earned its place in the supply chain toolkit, but not because it is a universal fix. Its power lies in being applied with precision, to close trust gaps where the risks are highest. By combining blockchain with lightweight collaboration tools, OEMs can create ecosystems that are both trustworthy and easy to participate in. The result is stronger compliance, healthier supplier relationships, and a more resilient value chain.

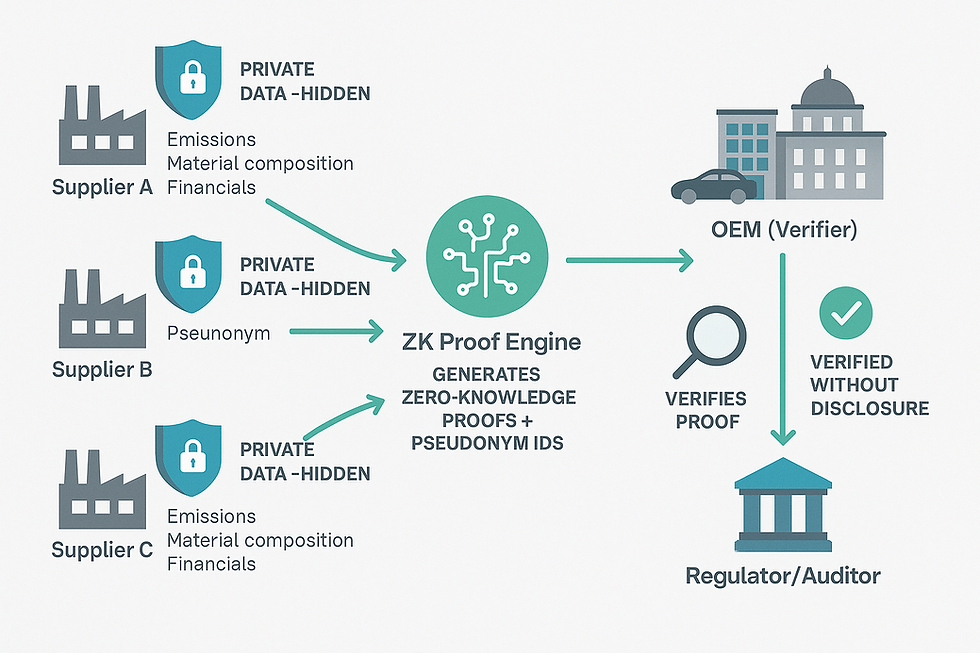

In our next discussion, we’ll move beyond blockchain and explore privacy-by-design approaches such as Zero-Knowledge pseudonyms. These methods will play a critical role in enabling collaboration while protecting supplier identities, marking the next evolution of trust in supply chains.

Comments